All aluminium parts need to be anodized in order to protect the surface and to make it look nice. Anodizing can be made in various colors. The NAP16 design required anodizing in nature "color", in black, in red and in gold.

All anodzing compoenets are bought from Ron Newman, MoonLite Focuser, who also sells very detailed description of how to get good results.

The aluminium parts need to go through several steps:

- Cleaning

- Etching

- Anodizing

- Coloring

- Sealing

To every single parts is attached a aluminium wire with good contact.

The anodizing process with an amp-meter to check current/surface.

The process requires accurate temperature. The current will heat up the bath and must be kept below 20C.

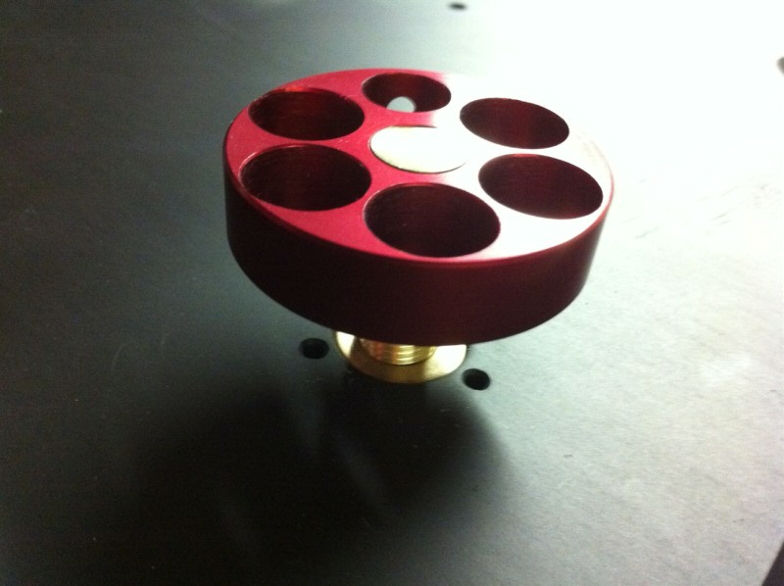

The first anodized part is the finger wheel.

All parts anodized.

NAP16 is now ready for assembly!